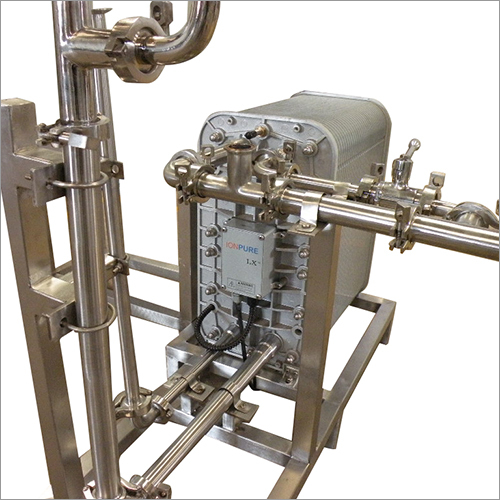

EDI Plant

1250000 INR/Unit

Product Details:

- Frequency 50/60 Hz Hertz (HZ)

- Ph Level 6.5 to 8.0

- Pump Type High pressure centrifugal

- Technology EDI (Electrodeionization)

- Power Consumption 2 to 5 kW Kilowatt (kW)

- Efficiency (%) up to 98%

- Recycle Rate up to 95%

- Click to View more

X

EDI Plant Price And Quantity

- 1 Piece

- 1250000 INR/Unit

EDI Plant Product Specifications

- Electric Motor

- 6.5 to 8.0

- Stainless Steel, FRP

- EDI (Electrodeionization) Plant

- Automatic

- up to 18 Megohm-cm

- 50/60 Hz Hertz (HZ)

- 250 LPH to 10,000 LPH Liter/day

- Pre & post micron, carbon filter

- < 20 S/cm

- Continuous operation, chemical free, low maintenance

- Electric

- Pharmaceutical, Power, Electronics, Laboratories

- 250 to 10000 LPH

- < 72 dB db

- 220-380 V Volt (v)

- Borewell water, municipal supply, industrial feed

- up to 98%

- Skid Mounted

- up to 95%

- 0.2 - 0.5 S/cm

- EDI (Electrodeionization)

- High pressure centrifugal

- 2 to 5 kW Kilowatt (kW)

EDI Plant Trade Information

- 7 Piece Per Month

- 2 Week

- WOODEN PACKAGING

- All India

Product Description

Our origination has gained dynamic reputation in the industry by presenting amazing arrangement of EDI Plant at competitive market price. EDI Plant is constructed with heady duty steel material and advances tools to give better performance and smooth applications. We offer excellent service which is highly appreciated by our consumers due to instant delivery and complete guidance as well as deep knowledge about the product. WE hired skilled personnel team to install and repaired the plant conveniently with hassle free condition.

Advanced PLC-Based Automation

This EDI Plant integrates a fully automatic PLC (Programmable Logic Controller) system, streamlining water purification with minimal human intervention. The intelligent control panel manages operations such as flow, pressure, and cleaning cycles, ensuring consistent performance and system safety. Designed to operate continuously with electric power, it guarantees reliability and user-friendly management.

Exceptional Water Purity for Critical Applications

Engineered to achieve deionized, ultra-pure water output suitable for stringent applications, the plant consistently delivers water with conductivity as low as 0.2 - 0.5 S/cm and a purity level up to 18 Megohm-cm. This makes it ideal for pharmaceutical production, laboratories, electronics, power generation, and other sectors requiring uncompromised water quality.

Efficient and Eco-Friendly Operation

Operating chemical-free and boasting a high recycle rate (up to 95%), this EDI plant minimizes water and chemical waste. Its low on maintenance due to durable components and high-quality stainless steel or FRP construction. The energy-efficient design (2 to 5 kW) ensures cost-effective and sustainable operation suitable for continuous industrial use.

FAQs of EDI Plant:

Q: How does the EDI Plant achieve ultra-pure water quality?

A: The EDI Plant combines reverse osmosis (RO) pre-treatment with electrodeionization technology, where spiral wound or plate and frame membranes further purify water. This process eliminates ions and impurities, producing ultra-pure, deionized water with conductivity as low as 0.2 - 0.5 S/cm and a high purity level up to 18 Megohm-cm.Q: What are the pre-treatment water requirements for the EDI Plant?

A: The system requires RO-treated water with an inlet conductivity below 20 S/cm as feed. This pre-treatment step is crucial to protect the EDI modules and ensure consistent, high-purity output for industrial applications.Q: When is the EDI Plant typically used?

A: This plant is deployed when process applications require high-purity, deionized water, such as in pharmaceutical manufacturing, power plants, laboratories, and electronics production. It supports continuous operation and meets the strictest water quality standards.Q: Where can the EDI Plant be installed, and what are the mounting options?

A: The EDI Plant is floor-mounted and comes as a skid-mounted system, making installation flexible for use in factories, laboratories, or industrial settings. Its dimensions are customizable based on capacity and site requirements.Q: What is the process flow of the EDI system?

A: Raw water first undergoes reverse osmosis filtration, reducing its conductivity. This pre-treated water enters the EDI module, where ion-exchange resins and an electrical current remove remaining dissolved ions. The process operates continuously and does not require chemical regeneration.Q: How long is the service life of EDI modules and what maintenance is needed?

A: EDI modules typically have a service life of up to 5 years. Maintenance requirements are minimal because the system is chemical-free and automated, though periodic checks and routine filter replacements are recommended to maintain optimal performance.Q: What are the key benefits of using an EDI Plant with PLC control?

A: This EDI Plant offers continuous, chemical-free operation, high efficiency (up to 98%), ultra-pure water output, and reduced operating costs. Its PLC-based automation simplifies system management, minimizes manual intervention, and enhances operational safety and reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

PURE OXIDANE TECHNOLOGY PRIVATE LIMITED

PURE OXIDANE TECHNOLOGY PRIVATE LIMITED Send Inquiry

Send Inquiry Send SMS

Send SMS